If you are looking for an epoxy floor coating to complete your commercial, industrial, or residential project, there are many different factors that should be considered prior to starting the installation process. One of the most important decisions will involve choosing between standard or more advanced materials. This article will discuss how an epoxy coating provides both durability and long-lasting beauty through a variety of designs, styles, and colors.

Epoxy Flooring Guide: Types of Epoxy

The different types of epoxy floor coatings vary in viscosity, color palette, texture, thickness, flexibility, and finish. So which do you choose? The answer to that question is likely determined by the location where the epoxy will be used and any budget concerns.

For example: if your garage needs a durable coat for its high traffic levels, but you have a limited budget – consider a standard urethane finish or satin-finish topcoat. A more advanced material with a glossier sheen may not be as cost-effective as this more budget-friendly option.

On the other hand, if you are looking for a high-quality flooring solution that will protect your property and make it more desirable to potential buyers, consider upgrading to an advanced material such as a polyaspartic or epoxy urethane with an HMA (hot mop) finish. These more expensive options will provide higher levels of durability and resistance while giving you unlimited design options for achieving tailored aesthetics.

Types of Epoxy Coatings:

Metallic Epoxy Coating: Metallic epoxy finishes create a sleek and modern look that elevates any commercial space. Metallic coatings are available in a wide range of colors, patterns, and textures.

Flake Epoxy Flooring: Flake epoxy finishes are designed to replicate the appearance of marble, granite, or other natural stone. Flake floors are often used in high-traffic locations due to their ability to resist scratches and scuffing.

Epoxy Mortar Flooring: Epoxy mortar floors are a great choice for any property owner who wants to make a true impression on prospects and tenants. The material is highly resistant to stains, chemicals, and abrasion from forklifts or other heavy machinery.

Epoxy Reactive Flooring: Epoxy reactive coatings contain pigments that require activation with specific wavelengths of light in order to achieve optimal color saturation. These epoxy finishes are often used outdoors because the pigments do not break down when exposed to UV rays or direct sunlight.

Anti-Static Epoxy: Anti-static epoxy coatings reduce the accumulation of dust and debris on a floor by generating an electrostatic charge that repels dust particles. This type of epoxy is most commonly used in warehouses, factories, and other commercial spaces where equipment such as forklifts or heavy machinery can produce static electricity.

Benefits of Using an Epoxy Coating

Not only are epoxy floor coatings extremely durable, but they will also create a surface that is slip-resistant regardless of whether it gets wet, is subjected to high-impact, or is walked on. While epoxy coatings are typically more expensive than other types of flooring solutions, they are also very cost-effective over the lifetime of the floor due to their extreme durability and resistance to damage.

Epoxy Coatings Can Last Up To 25 Years

Epoxy coatings can last up to 25 years or more, making them an affordable investment for property owners who want to improve the appearance of their commercial space while also increasing stability and safety.

Epoxy Flooring Guide: Maintenance Tips for Epoxy Coatings

Epoxy finishes are considered one of the most advanced floor coatings available, but they do require routine maintenance in order to retain both their beauty and durability. The good news is that most commercial epoxy coatings are very easy to care for and will generally only need regular mopping or sweeping in order to maintain optimal performance.

Here are some crucial steps you should follow to keep your epoxy coating looking sleek and new:

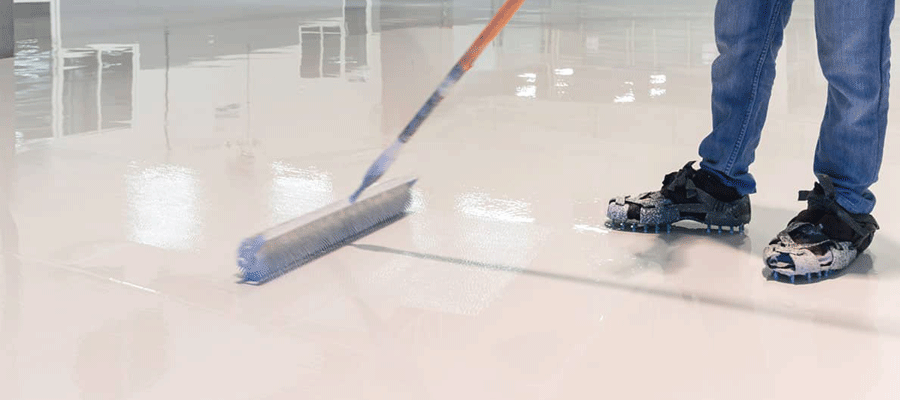

Step 1: Sweep or Mop the Floor to Remove Dirt and Debris

For many epoxy coatings, sweeping is typically enough in order to keep a floor looking sleek and beautiful. However, if you notice that your floor requires more than just a few quick sweeps before it is clean and dry, use a mop instead of a broom.

Step 2: Treat Any Scratches or Chips Immediately

While epoxy coatings are known for their ability to resist scratches and scuffs, they can also be somewhat sensitive to damage. In the event that your property is damaged, whether it’s from a forklift accident or simply from employees dragging furniture across the floor, you should immediately treat any scratches or chips with a floor repair kit.

Step 3: Apply a Protective Sealer

In order to prevent the formation of new scratches and scuffs, you should apply a protective sealer once per week to your epoxy coating. This simple step will preserve the look and durability of your commercial epoxy floor and help to keep it looking brand new for many years to come.

Step 4: Maintain Temperature and Humidity Levels

In order to prevent moisture from damaging your epoxy coating, you should also check the temperature and humidity levels in your commercial space. If either of these factors is too high or low, it could force the epoxy coating to expand or collapse, which will cause cracking and other types of damage. You can improve both temperature and humidity by installing a dehumidifier or an air conditioning unit, which will also help to improve the indoor air quality in your commercial space.

Step 5: Use the Proper Cleaning Tools

While you can clean an epoxy floor using pretty much any type of cleaning product or solution, it’s also important to use the right tools. If you’re using a mop or broom, make sure that they are made of either natural or synthetic materials. You should also avoid using vacuums with beater bars, as they could damage the epoxy coating over time.

Epoxy Flooring Guide: Conclusion

An epoxy floor can add a touch of elegance and industrial appeal to any commercial space while at the same time increasing stability and safety. However, in order to ensure that an epoxy coating remains in good condition, it is crucial to regularly sweep or mop the floor, apply a protective sealer once per week, maintain optimal temperature and humidity levels, and clean the floor using the right tools. By following these simple maintenance steps, you can help to ensure that your epoxy coating remains sleek and beautiful for many years to come.